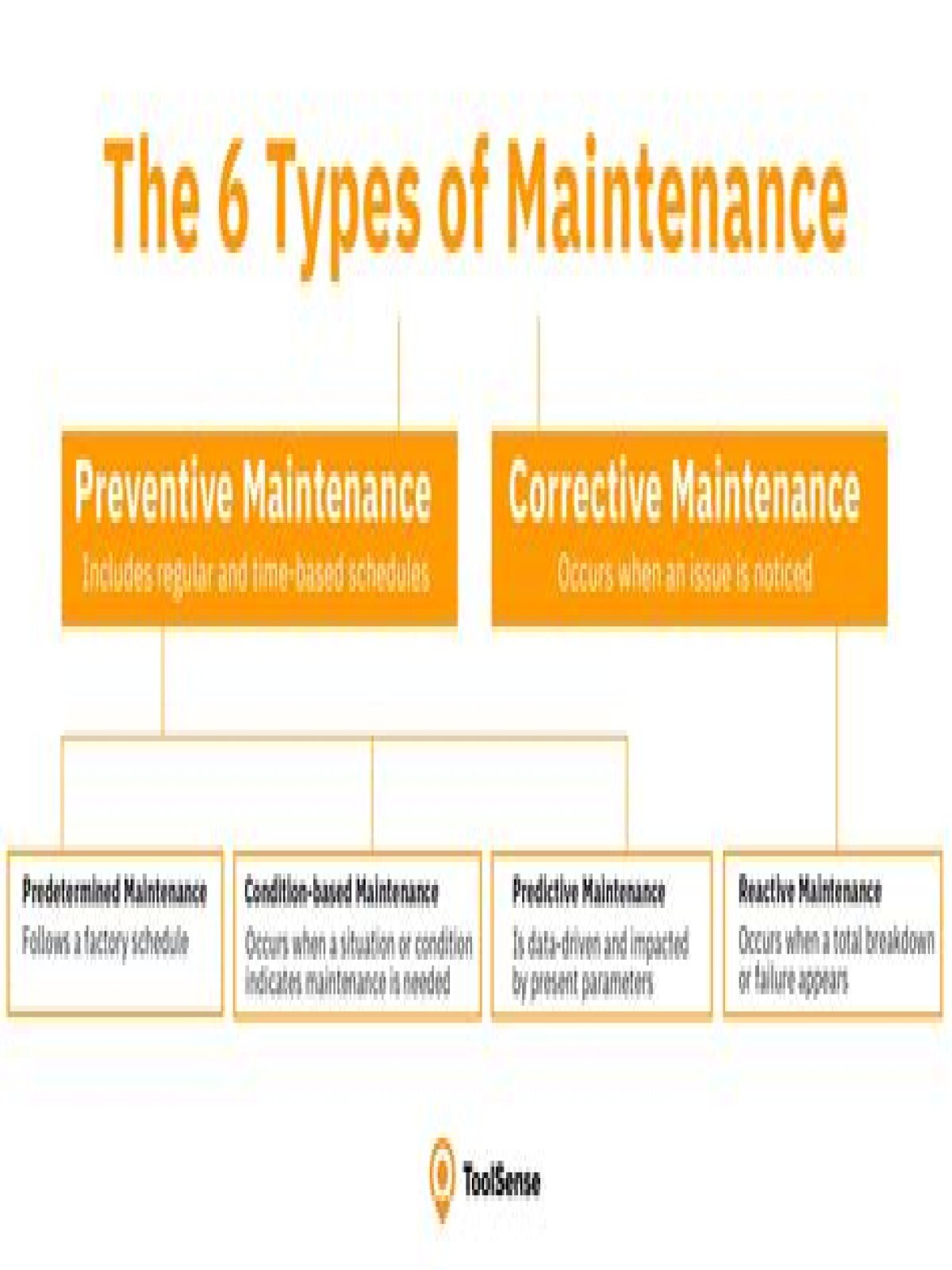

What are the types of maintenance services

Reactive (run-to-failure)Predetermined maintenance.Preventive maintenance.Corrective maintenance.Condition-based maintenance.Predictive maintenance.

- What is maintenance example?

- What do you mean by maintenance?

- What is facility maintenance services?

- What are the 4 types of maintenance?

- What is the importance of maintenance?

- What is the main purpose of maintenance?

- What is breakdown maintenance?

- What are the duties of maintenance?

- What do you mean by maintenance management?

- What are the 3 types of maintenance?

- What are the 5 types of maintenance?

- What is maintenance and its type?

- What is maintenance approach?

- How can we improve maintenance?

- What are basic maintenance skills?

- Does maintenance mean cleaning?

- How is routine maintenance done?

- What is schedule maintenance?

- What is difference between breakdown maintenance and corrective maintenance?

- What is preventive maintenance?

- What are the two main types of maintenance?

What is maintenance example?

The definition of maintenance is providing support or upkeep to something. An example of maintenance is a janitor keeping a school clean.

What do you mean by maintenance?

The work of keeping something in proper condition, care or upkeep including: taking steps to avoid something breaking down (preventative maintenance) and bringing something back to working order (corrective maintenance).

What is facility maintenance services?

Facilities Maintenance, Service Requests and Projects Overview. Definition of “Facilities Maintenance” Maintenance activities include keeping spaces, structures and infrastructure in proper operating condition in a routine, scheduled, or anticipated fashion to prevent failure and/or degradation.What are the 4 types of maintenance?

Four general types of maintenance philosophies can be identified, namely corrective, preventive, risk-based and condition-based maintenance.

What is the importance of maintenance?

Maintenance is an important factor in quality assurance and in some cases determines the long-term success of a company. Poorly maintained resources can cause instability and partially or completely pause the production. Malfunctioning machines or complete breakdowns can become a costly process for most companies.

What is the main purpose of maintenance?

The purpose of maintenance is to ensure the maximum efficiency and availability of production equipment, utilities and related facilities at optimal cost and under satisfactory conditions of quality, safety and protection for the environment.

What is breakdown maintenance?

Breakdown maintenance is maintenance performed on equipment that has broken down and is unusable. It is based on a breakdown maintenance trigger. It may be either planned or unplanned.What are the duties of maintenance?

- Maintaining records of any work and inspections done on-premises.

- Performing inventory on repair supplies.

- Keeping repair tools and supplies clean and organized.

- Setting up repair appointments with mechanics or electricians when needed.

- Making and installing new furniture or equipment.

Building maintenance refers to all tasks necessary for keeping a building functional and livable. A single building requires a skilled team of multiple people with different maintenance specialties in areas like electrical, plumbing, and HVAC.

Article first time published onWhat do you mean by maintenance management?

Maintenance management is defined as the process of maintaining the assets and resources of a company, which has as main objective to control and reduce costs, times, and resources. It goes through the regular monitoring of the functioning of machines, equipment, facilities, and tools.

What are the 3 types of maintenance?

- Corrective Maintenance.

- Preventative Maintenance.

- Predictive Maintenance.

What are the 5 types of maintenance?

Five types of maintenance are in fact recurrent in the industry: corrective, preventive, condition-based, predictive and predetermined.

What is maintenance and its type?

Maintenance, in general, can be defined as efforts taken to keep the condition and performance of a machine always like the condition and performance of the machine when it is still new. Maintenance activities can basically be divided into two parts: planned maintenance activities and unplanned maintenance activities.

What is maintenance approach?

Maintenance approaches can involve monitoring equipment for problems or fixing a machine after it breaks down. … A scheduled stop in production which is often used for machine maintenance. Planned downtime is preferable to unplanned downtime, which is usually caused by machine failure. predictive maintenance. PdM.

How can we improve maintenance?

- Learn the 12 elements of effective reliability management. …

- Track maintenance metrics. …

- Employ maintenance planning and scheduling. …

- Consider an operator-driven reliability program. …

- Improve basic work systems. …

- Use joint reward systems to drive results. …

- Construct your maintenance plan.

What are basic maintenance skills?

- Technical skills. …

- Interpersonal and communication skills. …

- Attention to detail. …

- Problem-solving skills. …

- Administrative and organizational skills. …

- Physical ability. …

- Flexibility and versatility. …

- Advanced skills.

Does maintenance mean cleaning?

Maintenance Cleaning means an activity carried out to keep general work areas, tools, machinery or equipment, excluding application equipment, in clean and good operational condition.

How is routine maintenance done?

Typical examples of routine maintenance include: Lubricating, cleaning, or adjusting machinery. Inspecting equipment to ensure proper operation and safety. … General workplace maintenance, such as cleaning floors, replacing HVAC filters, and washing windows, trash removal, and landscaping.

What is schedule maintenance?

Scheduled maintenance is any task that is given a deadline and assigned to a technician. It can either be a recurring task done at regular intervals or a one-time task. Scheduled maintenance includes inspections, adjustments, regular service, and planned shutdowns.

What is difference between breakdown maintenance and corrective maintenance?

Preventive maintenance refers to maintenance tasks that are performed on a repeated schedule to prevent failures. … Breakdown maintenance, also referred to as corrective maintenance, is a strategy that performs maintenance tasks only after an asset fails. Maintenance tasks are only performed when they become urgent.

What is preventive maintenance?

Preventive maintenance (PM) is the regular and routine maintenance of equipment and assets in order to keep them running and prevent any costly unplanned downtime from unexpected equipment failure. A successful maintenance strategy requires planning and scheduling maintenance of equipment before a problem occurs.

What are the two main types of maintenance?

Most types of maintenance fall under two main categories: preventive and corrective. Preventive maintenance is when you proactively initiate tasks and maintenance plans to prevent failures from occurring.